BAE Systems has unveiled a new manufacturing process for explosive material used in various high explosive munitions. Under development for four years, the explosive material produced using this process offers increased explosive and penetrative power, with additional benefits including more efficient and safer manufacturing.

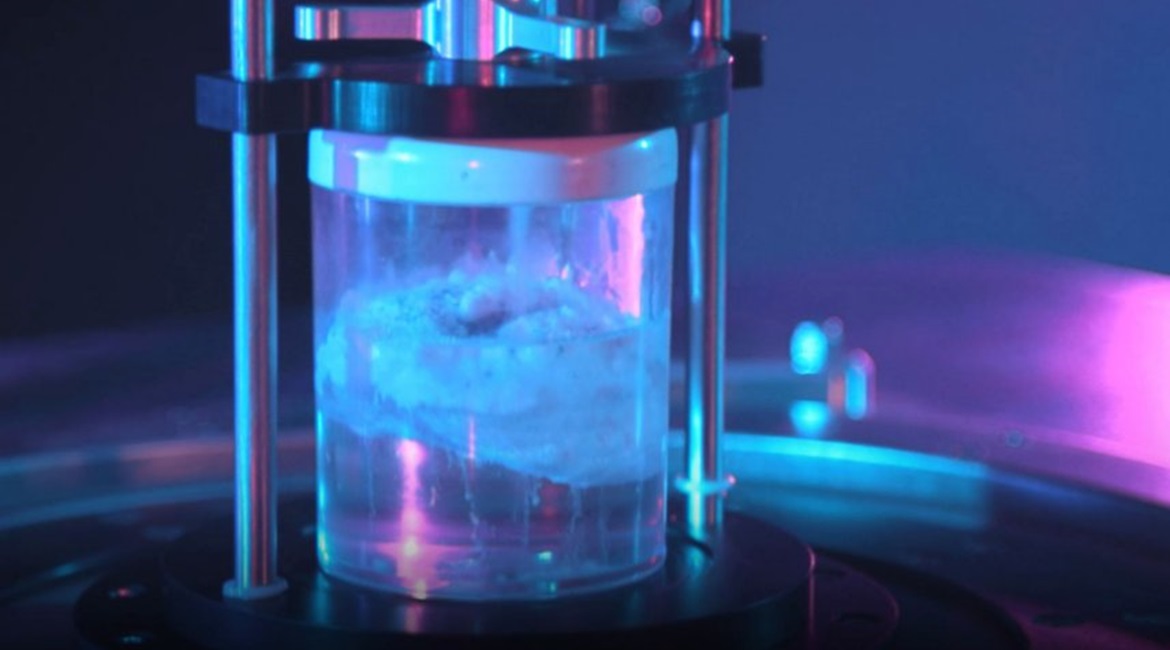

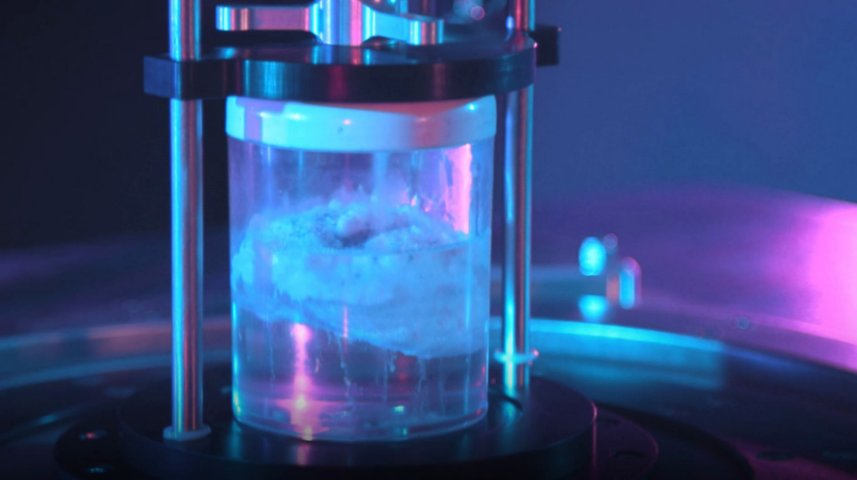

Explosives produced using Resonant Acoustic Mixing techniques promise to take up less space and be safer to manufacture. (BAE Systems)

The process tested involved Resonant Acoustic Mixing (RAM) technology originally developed by Resodyn in place of the more traditional blade mixing method. RAM generates a high level of energy by continuously operating at the resonant frequency of the mixer. This enables all forcing energy to be applied directly onto the ingredients being mixed in a higher number of mixing zones. The system monitors itself to ensure it can deliver the greatest amplitude/displacement for the least amount of power.

In the test portrayed by BAE Systems, 400 g of polymer bonded explosive mixture was produced through the RAM technique. This was placed within a small shaped charge (equivalent in size to a soup can) and connected to an electric detonator, where it underwent an Energetic Materials Testing Assessment Policy Manual of Tests (EMTAP) shaped-charge test. The resulting detonation penetrated nine 1-inch mild steel plates and showed a 20% increase in explosive and penetrative power when compared against equivalent explosive mixtures produced by more traditional means.

According to BAE Systems, using RAM’s acoustic fields allowed the usage of more viscous liquids for the mixture and removed the need for “solvents” traditionally used to facilitate blade movement. This resulted in a “purer” explosive mixture.

Looking to read the full article?

Gain unlimited access to Janes news and more...