The Bundeswehr has decided not to take delivery of two A400M transport aircraft due to “technical deficiencies” and because “they do not possess the contractually guaranteed performance”, the Luftwaffe announced in a press release on 13 November.

The press release cited as an example of recurrent technical problems that routine inspections of the propeller assembly of Luftwaffe A400Ms already flying discovered that not all the 24 nuts per propeller have the intended torque load. Failure to detect and correct this could result in severe structural damage to the propeller and shaft of the propeller gearbox, according to the Luftwaffe.

The service said additional inspections were recently introduced to check the torque load of the nuts. The time required depends on the results of the checks but as an inspection takes about 30 hours it means that the aircraft is not available for a day, the Lufwaffe explained.

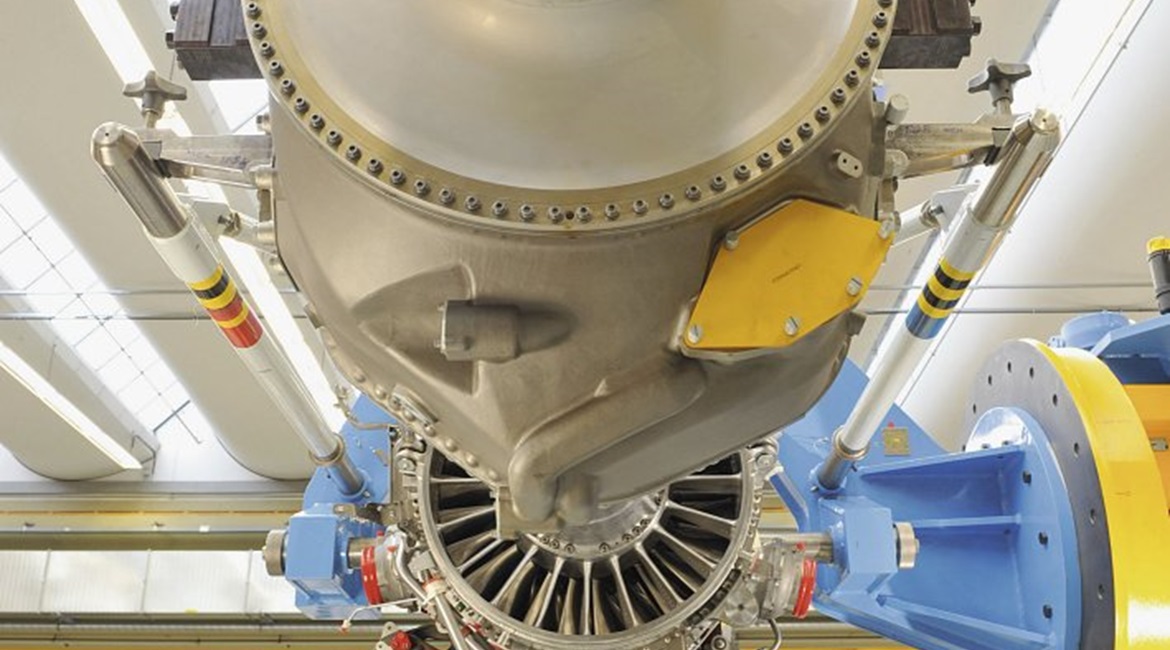

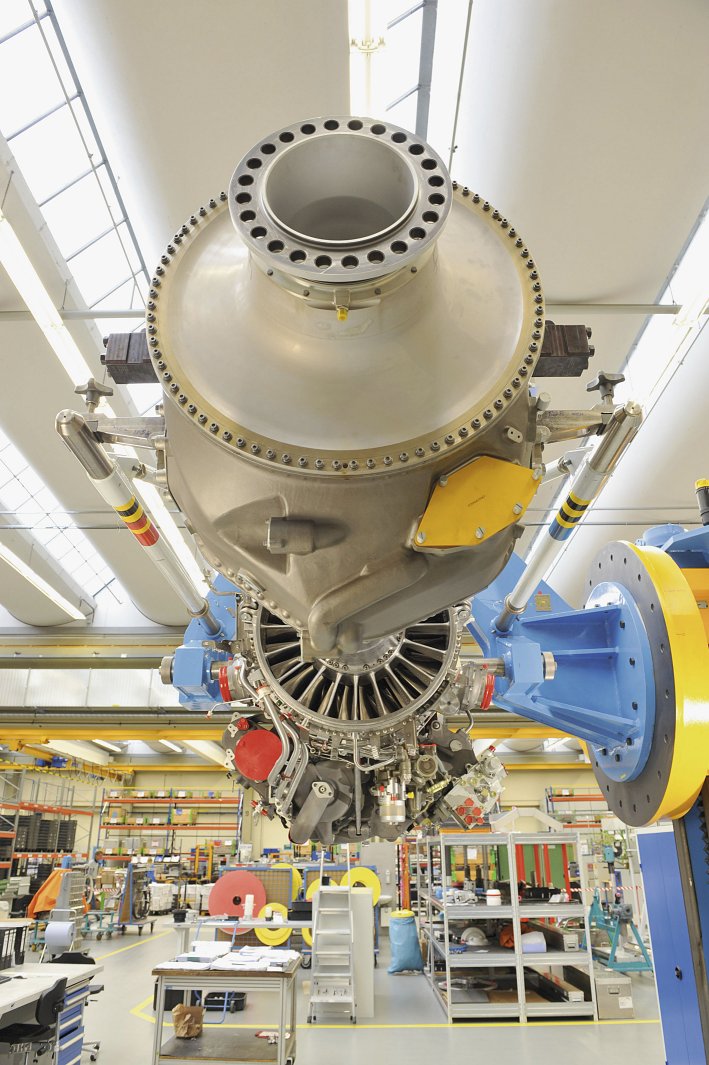

Luftwaffe inspections of the propeller assembly of its A400Ms have found that not all the 24 nuts per propeller have the intended torque load. (EPI)

The service added that inspections are also required of the engine mounts, combustion chambers, and engine flaps, as well as to check for cracks.

“We are aware of findings related to dowel bolts/propeller interface in some of our customers’ aircraft. The issue, already communicated to all our customers, requires inspection/torque checks on propeller interface bolts for aircraft involved in demanding high G manoeuvre operations,” an Airbus Defence and Space spokesperson told Jane’s on 13 November.

“This is not safety critical and our customers continue to accept and operate their aircraft,” according to Airbus, which said it “is working together with EPI [Europrop International] and Ratier[-Figeac] to alleviate the inspections regime and use the already existing maintenance schedule”.

Looking to read the full article?

Gain unlimited access to Janes news and more...