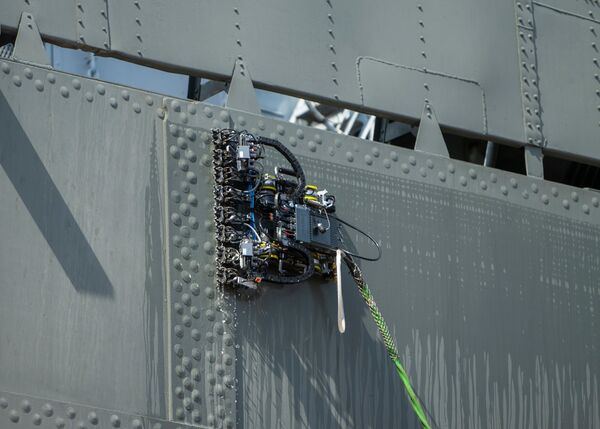

Gecko Robotics employs robotic platforms with modified sensor payloads to survey ships for maintenance and new construction work. (Gecko Robotics)

Technology that mates robotics, sensors, and artificial intelligence (AI) is being used to speed repairs and new construction work on aircraft carriers, submarines, and surface ships as the US Navy (USN) tries to reduce the backlog in ship-work programmes.

Gecko Robotics outfits different types of mobile robotic structures with especially developed and modified acoustic and optical sensors and cameras to provide a data-rich representation of ship structures to a degree and depth the navy has not had before and then uses AI to process and analyse that data and offer the navy recommendations on how to improve repair work or construction, according to the company.

“And what we're really trying to do is to be predicative,” Jake Loosararian, Gecko Robotics cofounder and CEO, told Janes in a 19 September interview.

The USN has found the Gecko Robotics technology worthwhile. The company estimates its work for the service's surface fleet has increased about 400% since last calendar year.

Gecko Robotics also told Janes that it finished a robotic investigation and analysis of a carrier flight deck in mid-October.

The company recently secured a contract to do similar work for new submarine construction, and the company also has a pending USD75 million indefinite delivery/indefinite quantity (ID/IQ) contract for automated vessel inspection and maintenance, which is being delayed due to US government administrative hurdles.

The submarine work comes at a time when submarine builder HII has acknowledged the discovery of failures to follow proper welding procedures at its Newport News Shipbuilding yard. Gecko Robotics notes its technology can be used to check on welding quality assurance.

Looking to read the full article?

Gain unlimited access to Janes news and more...