Companies that churn out military jets and tanks would not normally be categorised as medical device manufacturers. But with demand for healthcare items far outpacing supply due to the rapid spread of the coronavirus (Covid-19), many defence firms are repurposing some of their factories to produce ventilators, protective face gear, and other equipment needed to fight the pandemic.

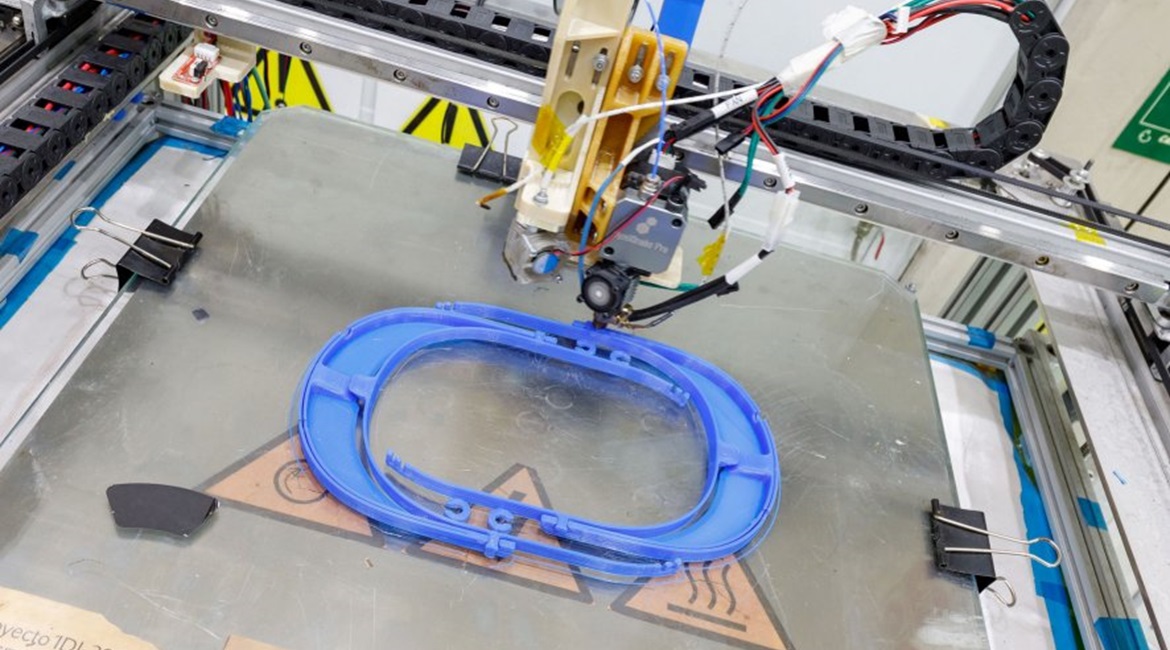

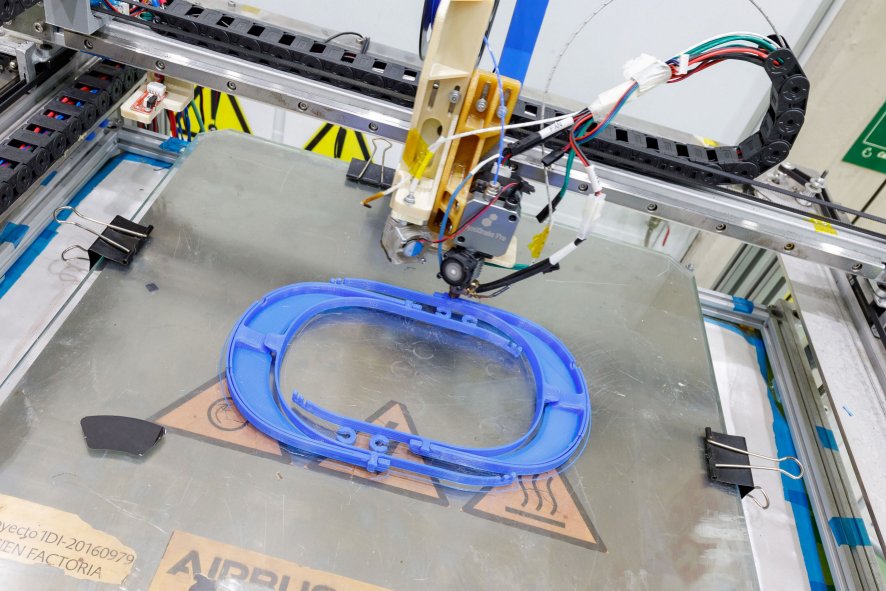

A 3D printer at an Airbus site in Spain makes frames for protective face shields (Airbus/Pablo Cabellos)

In the UK, Airbus, BAE Systems, Cobham, Rolls-Royce, Thales, and other defence firms have joined with automotive and medical companies to form Ventilator Challenge UK Consortium, which aims to assemble thousands of ventilators for the country’s National Health Service (NHS).

Airbus, for example, has installed new production lines at its site in Broughton, North Wales, which will make ventilators based on an existing breathing aid, a consortium spokesperson said.

Cobham has developed a key ventilator part by modifying hardware used in military aircraft oxygen systems. The part is an air pressure regulator that controls the flow of oxygen to a patient.

UK defence firms are also making other medical products. BAE Systems employees who normally work on combat aircraft and submarine programmes are 3D printing face shield parts. BAE and its suppliers expect to deliver more than 120,000 face shields to the NHS this month.

“We’ve all been moved by the personal bravery of those working in the NHS who face the virus close up every day, so we wanted to help in any way we could,” said Dave Short, BAE technology director.

Rolls-Royce said its “employees have been working around the clock to 3D print face shields for healthcare workers.” Cobham has adapted “high-performing” space electronics to study how the coronavirus is transmitted and how it evolves.

Looking to read the full article?

Gain unlimited access to Janes news and more...